What is Bulk Material Handling Equipment?

Bulk material handling equipment refers to a wide range of machinery, devices, and systems used for efficiently handling, moving, storing, and processing large quantities of bulk materials. Bulk material handling equipment is essential in industries that deal with loose, granular, or free-flowing substances in large volumes, such as mining, construction, agriculture, manufacturing, and logistics.

What are the objectives of bulk material handling equipment?

The primary objectives of this equipment include the transport of materials from one location to another, the provision of storage solutions, the loading and unloading of materials onto transportation vehicles, and the processing of materials through crushing, grinding, screening, mixing, or other necessary steps. These equipment systems, such as conveyors, hoppers, loaders, crushers, and dust collection systems, play a crucial role in industries that deal with bulk materials, facilitating seamless material flow, enhancing productivity, and ensuring efficient operations.

What are some types of this equipment and what do they do?

Bulk material handling equipment encompasses a diverse range of machinery, devices, and systems tailored to efficiently handle, transport, store, and process large volumes of loose or granular materials.

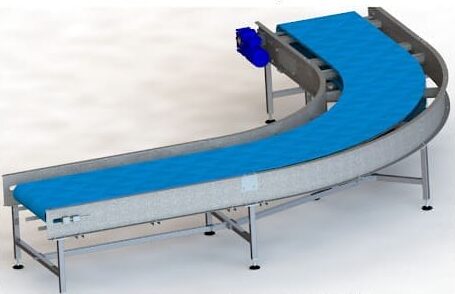

- Conveyor systems, including belt conveyors, screw conveyors, pneumatic conveyors, and bucket elevators, facilitate the smooth movement of materials over short or long distances.

- Hoppers and silos provide temporary storage solutions, while loaders, unloaders, and cranes facilitate the loading and unloading of materials onto trucks, ships, or railcars.

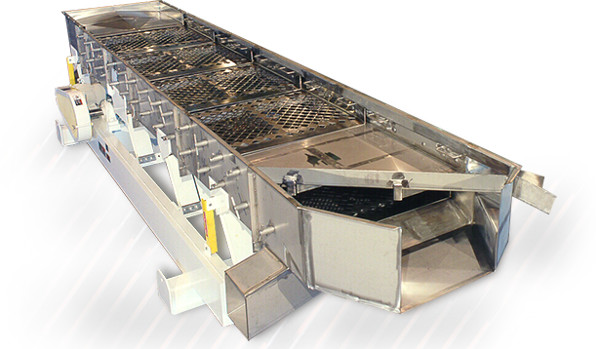

- Crushing and screening equipment, such as crushers, screens, and classifiers, are employed to modify the size or grade of bulk materials, while mixers and blenders ensure uniformity by combining different materials.

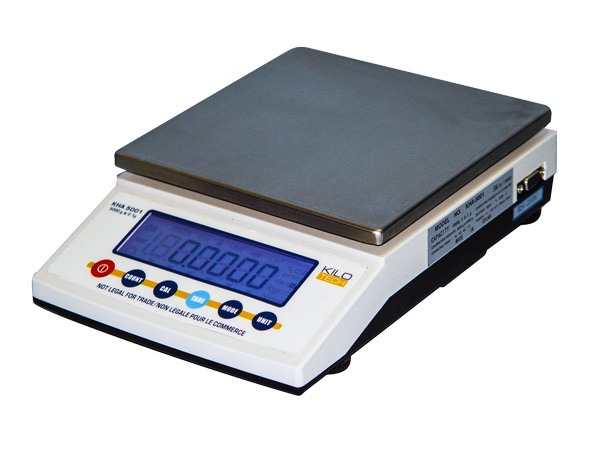

- Weighing and measuring systems accurately measure quantities, and dust collection systems control airborne particles generated during handling.

These types of equipment collectively optimize material flow, enhance productivity, and streamline operations in industries dealing with bulk materials.

Bulk material handling equipment is used to transport, process, and package bulk materials, like powder bulk solids, before sale or shipment. There are many different types of bulk material handling systems which are distinguished by the types of applications for which they are used and the kinds of materials they are constructed to handle.

Bulk material handling systems

A bulk material handling system refers to a comprehensive arrangement of equipment, infrastructure, control systems, and automation technology designed to efficiently handle, transport, store, and process large quantities of bulk materials. It undergoes a coordinated network of safety and environmental considerations before integration as a successful system

What is the function of each component in this system?

As mentioned, a bulk material handling system typically includes several key elements. Below we examine each of these components, and their function, in greater detail.

Equipment: This comprises the machinery and devices specifically designed for handling bulk materials, such as conveyors, hoppers, loaders, crushers, screens, mixers, and storage silos. Each piece of equipment plays a specific role in the overall system.

Infrastructure: The system requires appropriate infrastructure to support the movement and storage of bulk materials. This can include conveyor belts, support structures, chutes, and access points for loading and unloading.

Controls and Automation: Advanced control systems and automation technology are often incorporated to monitor and control the operation of the bulk material handling system. These systems ensure efficient material flow, manage equipment synchronization, and enable process optimization.

Safety and Environmental Considerations: Bulk material handling systems prioritize safety measures to protect workers and prevent accidents. Additionally, environmental considerations, such as dust control and spillage prevention, are taken into account to minimize the impact on the surroundings.

Integration: A bulk material handling system is designed to seamlessly integrate various components, allowing for the smooth transfer of materials between different equipment and stages of the process. Integration ensures a continuous and efficient flow of bulk materials.

The purpose of a bulk material handling system is to enable the efficient and reliable handling of large volumes of bulk materials, ensuring their proper movement, storage, and processing. These systems are widely used in industries such as mining, agriculture, construction, manufacturing, and logistics, where the handling of bulk materials is a fundamental aspect of operations. By employing a well-designed bulk material handling system, organizations can enhance productivity, minimize manual labor, optimize resource utilization, and improve overall operational efficiency.

What kinds of equipment are used in a bulk material handling system?

Bulk material equipment and systems are manufactured according to the task that each unit is supposed to accomplish, but most systems incorporate the same general components and features. A full system generally features:

An unloading station. The system must have an access point where materials can be discharged into the system. This portion of the system can take many forms, ranging from railcar unloading stations to a simple bag dumping station.

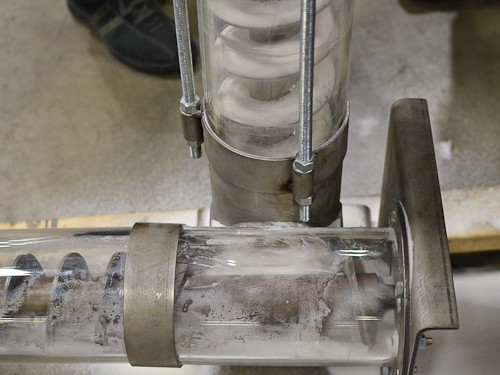

A conveying system. Most often bulk material handling systems utilize pneumatic conveyors, but other systems use screw conveyors, bucket elevators, or drag chain conveyors. Many systems use a combination of two or more of these different conveyors.

Material storage equipment. From huge storage silos to small bins or hoppers, a bulk material handling system should have a location where materials are stored until they are needed for processing.

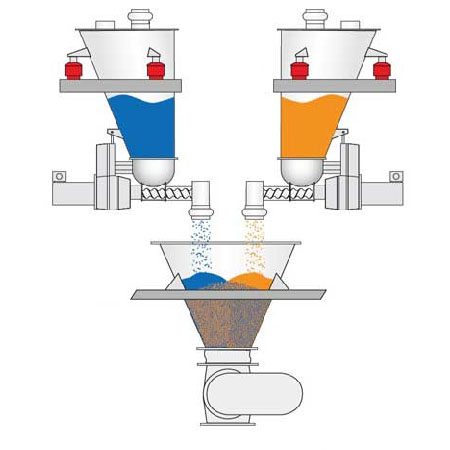

Batching equipment. In order to utilize bulk materials efficiently, batching equipment is used to accurately dispense bulk materials for processing and for packaging.

A filling or packaging station. Once the bulk materials have been processed, the system needs a method for offloading the final product for packaging, shipment, or sale.

Are there variations of bulk material handling systems?

While practically all bulk material handling systems incorporate these main kinds of equipment, each system may use slightly different variations of the equipment and incorporate additional components to fit the specific needs of the application at hand. For example, in a food processing facility, a bulk material handling system would most likely use large storage silos instead of smaller storage bins, since they often handle such large quantities of grains, powders, and other materials. Additionally, some systems are designed to better transport and handle materials composed of very small particles, while others efficiently convey larger granules.Bulk material handling systems can be highly customized to fit the specific requirements of a given task or process.

What factors should I consider when assembling a bulk material handling system?

When assembling a bulk material handling system, several factors should be considered to ensure its effectiveness and efficiency.

First, it is essential to assess the specific characteristics of the bulk materials being handled, including their size, shape, density, flow properties, and any special handling requirements. This information helps in selecting the appropriate equipment and determining the system’s capacity and configuration.

Next, the desired material flow rate and the distances over which materials need to be transported should be considered to determine the appropriate conveyor types and lengths. Additionally, the available space and layout of the facility should be assessed to design an optimal arrangement of equipment, considering factors such as accessibility, clearances, and potential bottlenecks. The system’s safety requirements, including guarding, emergency stops, and ventilation for dust control, should also be carefully evaluated and integrated.

Finally, considering future scalability, maintenance requirements, and potential expansion plans can help ensure that the bulk material handling system can accommodate future growth and adapt to changing needs. By considering these factors comprehensively, a well-designed bulk material handling system can be assembled to enhance efficiency, productivity, and safety in handling large volumes of materials.

There are a number of considerations that have to be made when bulk material equipment or systems are being installed.

Not all equipment is made for use with all types of material, and the consistency of the material will greatly affect the quality of the final product. Some factors that should be considered during equipment selection are:

- •Bulk density

- •Average particle size

- •Particle properties

- •Environmental effects

- •Material base

Experts recommend conducting extensive material tests before purchasing equipment so that the necessary processing qualities can be understood. For example, some particle densities actually change at different stages of the material handling process, so it should not be assumed that each piece of equipment will function efficiently at the same density level.

Pneumatic conveyors are the backbone of most bulk material handling systems, so these considerations are incredibly important for determining which kind of pneumatic conveyor will transport specific bulk solids most effectively.

Abrasive materials cannot be transported in the same way that a sticky material would be transported, for example.

Some materials may transport more effectively using dense phase conveying, while others are effectively transported with dilute phase conveying methods.

While these considerations are most vital for conveying systems, they do also affect other handling components, but to a lesser extent. Particle size and cohesion affect how materials can be combined together and can affect how the material is dispensed. Which means that material properties should also be considered for batching equipment, mixers, and material feeders.

Why would I need this equipment or system?

Bulk material handling equipment or a bulk material handling system is crucial for your business for several reasons. To begin with, it enables efficient material handling, allowing for the movement, transportation, and storage of large volumes of materials. This efficiency leads to cost savings, improved productivity, and streamlined operations. Next, the use of specialized equipment ensures the safe handling of bulk materials, reducing the risk of accidents or injuries to workers. Additionally, the equipment enables precise control and measurement of materials, ensuring accurate dosing, batching, and inventory management. This promotes consistency in product quality and reduces waste. Moreover, bulk material handling equipment improves overall operational flexibility, allowing you to adapt to changing production demands or market requirements. It also enhances scalability, enabling you to handle increased volumes as your business grows. Ultimately, investing in bulk material handling equipment or systems can boost efficiency, safety, quality control, and overall profitability for your business.

Do I need bulk material handling equipment or a system?

Determining whether you need bulk material handling equipment or a bulk material handling system depends on the scale, complexity, and requirements of your material handling operations. If you have a small-scale operation with straightforward needs, standalone equipment may suffice. However, if you have multiple steps, require integrated workflows, aim to enhance efficiency and productivity, prioritize safety and compliance, and anticipate future growth or expansion, a comprehensive bulk material handling system is more suitable. Such a system offers seamless material flow, optimized workflows, scalability, and enhanced safety features. Assessing your specific needs and considering factors like integration, productivity, safety, and scalability will help guide you in making the appropriate choice. Consulting with industry experts can provide valuable guidance tailored to your circumstances.

What does the future hold for bulk handling equipment and systems?

Bulk material handling equipment and systems are expected to play a significant role in the future for several reasons, which may influence your decision to invest in them. To start, as industries continue to grow and evolve, there will likely be an increasing demand for efficient handling of bulk materials. The ability to handle large volumes quickly, accurately, and safely provided by bulk material handling equipment and systems could be crucial for maintaining your competitive advantage. Additionally, advancements in technology, such as automation, robotics, and data analytics, should transform the field of material handling. Integrating smart technologies into bulk material handling systems could optimize your processes, improve productivity, and provide valuable insights for decision-making. Furthermore, as sustainability and environmental considerations gain prominence, bulk material handling equipment and systems are being designed with energy efficiency, waste reduction, and emissions control in mind. By adopting these environmentally friendly solutions, your business would readily meet regulatory requirements and, perhaps more importantly, contribute to a greener future. Ultimately, investing in bulk material handling equipment and systems should equip your business with the capabilities to meet future demands, embrace technological advancements, and align with sustainable practices, positioning you for long-term success.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services