Bulk materials range in size, texture and density. They are used for many industrial and commercial applications, and many of them need to be processed differently. Wet bulk materials, for example, are typically much denser and heavier than dry materials. A bulk material handling system, or the individual pieces of equipment within that system, must to be selected based on the type of material that is being processed. When selecting the right equipment, there are a variety of important factors to consider:

- Production size – How much material will you be moving in your facility on a regular basis? This will determine what kind of conveyor you use.

- Distance – How far do the materials need to be moved? If it is a short distance with a low volume, hand trucks might be fine. A longer distance will need carts or heavy conveyors.

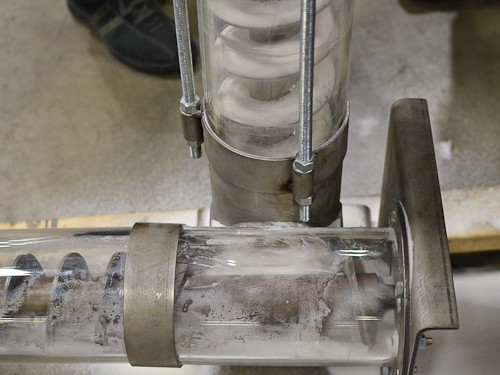

- Physical State – Is your bulk material a solid or a liquid? You don’t want to run liquid bulk material on an open mechanical conveyor or in a dry mixing tank.

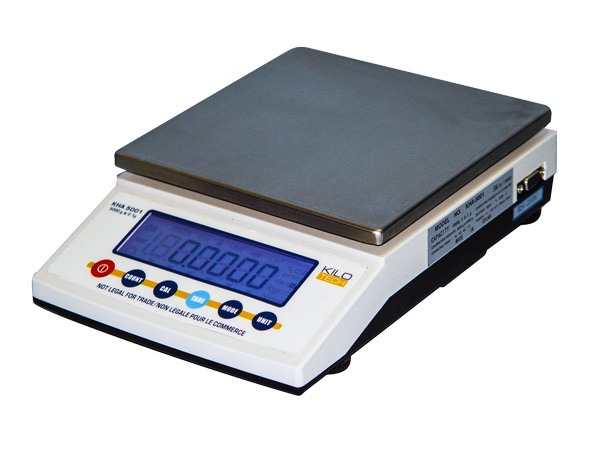

- Weight – How heavy is your material per piece or unit?

- Shape – Is the material in pellets? Is it round or are the particles very small and grainy? These shapes will all yield different flow patterns.

- Hazard – Is the material toxic, flammable or explosive? Extra care will need to be taken during handling if the material poses any danger to people in the surrounding area.

Besides these considerations, bulk material handling engineers also need to think about the available space for the system in the new or existing plant. Some bulk material equipment can be very large and it may not fit in a limited floorspace. In spaces with an unusual configuration, engineers design customized machinery to work with the available area. In a brand new bulk material handling operation, it is ideal that the facility is built after the system is designed. However, this rarely happens so engineers need to make systems work in existing structures.

Dry Bulk Materials

Dry Bulk Materials Wet Bulk Materials

Wet Bulk Materials

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services