Fill/Load

Filling containers, bags and bins is a critical part of any bulk material handling system. Without the right equipment, this can be a very difficult task to accomplish. However, with the right equipment from trusted manufacturers, filling can take place in second with as little as the push of a button. Filling machines come in various sizes and styles for a variety of applications. A bulk bag filler can be mounted over a bag and secured firmly to the mouth of the bulk bag before the door is opened and the dry bulk materials are released into it through a hopper. Securing the neck of the bag around the filler seal prevents any materials from being lost and reduces dust during transfer. The flow rate can be adjusted by opening or closing the fill valve.

In bulk handling settings that involve marine transport via a major shipping vessel, the materials are carried along a conveyor on a boom to a slew that guides them into the cargo hold of the vessel. This slew enables the operator to fill the cargo hold to complete capacity by moving it around so that the material is spread evenly through the space.

Some filling machines eject the bulk material laterally into a large storage bin so that it is distributed evenly. This is done by loading the material into a hopper that feeds into the filling machine. The filling machine carries the material between two conveyor belts that are moving quick, and then shoots it out the side and into the opening of the bulk storage bin. Shipping crates in a shipyard can be loaded quickly this way without ever having to be taken off the back of a truck.

Quality filling equipment reduces lost or wasted material and increases efficiency during the bulk material handling process. Integrated and highly advanced controls make it possible to operate equipment in on customized settings that are best suited to your bulk filling needs. Some companies with in-house bulk handling system engineering specialists will even design a customized solution for you that works with your material and desired flow volume.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

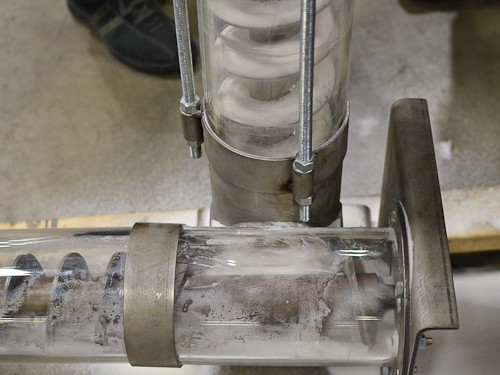

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

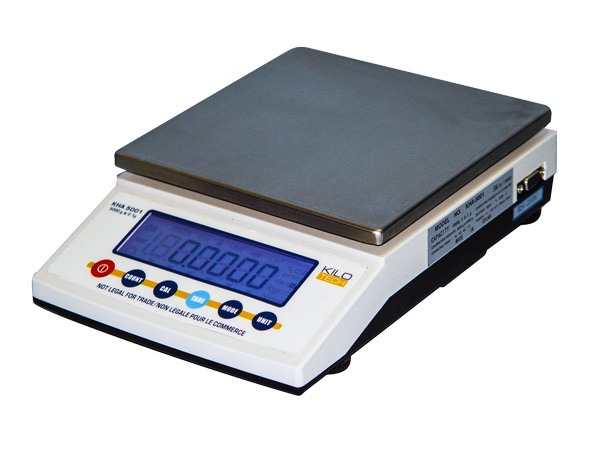

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services