Clean

To operate as efficiently as possible, it is very important that bulk material handling systems are cleaned periodically. This can include cleaning out silos, bins, hoppers, railcars, pneumatic tubing and any other part of the system where material could build up. Removing any built up material will restore proper material flow, prevent cross-contamination and recover any lost material. Some facilities have personnel and equipment on-site to perform these cleaning jobs themselves, while others hire cleaning specialists to come in during scheduled down times and thoroughly clean the inside of all of the equipment. The frequency of cleaning really depends on the size of the system and the types of materials being handled. If the material is always different and there is a high chance of cross-contamination, then cleaning will be a regular activity.

A variety of tools and methods are used to clean a bulk material handling system. To loosen material that is lodged in bins, a whip bin tool is often used. This tool can be lowered into the bin using a boom and controlled remotely. The arms to the tool spin rapidly, stirring up settled material and removing any material that is stuck to the wall of the bin. Sometimes, if bulk material is stored for an extended period, it settles and becomes hard. The fully controllable tool can be moved throughout the entire bin to loosen all of the material. Other tools include a bin drill, a small drill that bores a hole through material in a vessel to create a flow channel, and a “Chunkbuster”. A chunkbuster is a high strength steel tube with liquid CO2 in it. When the contents of the tube are energized, they immediately turn to expanding gas which pushes any material in the tube. This tube can be mounted at build-up locations on a vessel and activated to restore flow.

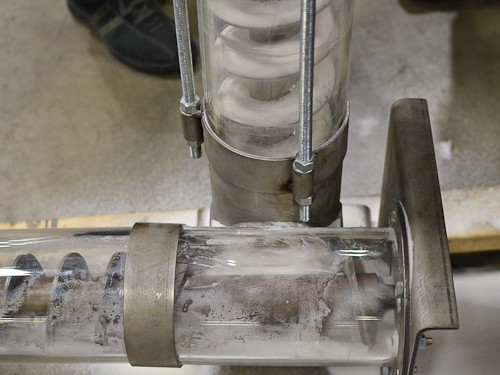

Fluid cleaning agents are used to sterilize or remove blockage from pneumatic tubes.These chemical solutions are made to quickly flush out an entire system by being run through in the same way that regular bulk material would be run through the system. This step prevents cross-contamination between materials. In any food processing facility, these cleaners need to be up to industry food safety standards so that harmful chemicals are not transferred into the bulk food ingredients being handled at the facility.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

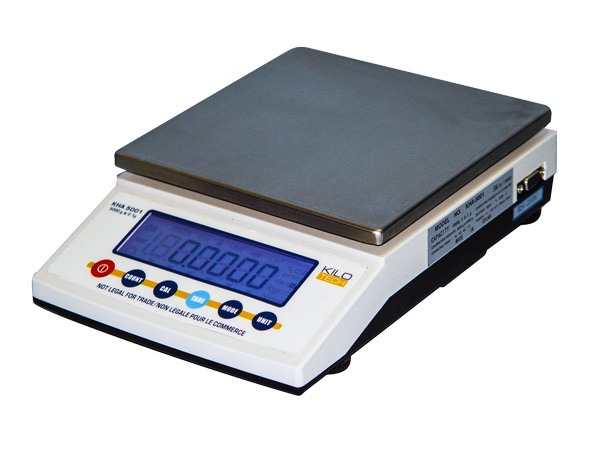

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services