Bulk material handlers in all industries rely on scales to weigh their products and accurately determine quantities during packaging, before shipping, or before storage in a facility. Many bulk products are sold or distributed based on weight, so it is important that precise information is available.

Load Cell Central open_in_new

Location: Milan, PA

Load Cell Central is a leading manufacturer of load cells and industrial weighing equipment. We specialize in standard and custom load cells and digital indicators, floor scales and platform scales. Choose from thousands of types and models. We offer load cell repair to help in the reduction of costs.

Fairbanks Scales open_in_new

Location: Overland Park, KS

Top quality industrial weighing equipment for 180 years. Call or click today to find a dependable Fairbanks rep near you. Always setting new standards in scale design, try our Weigh in Motion systems – high speed package scales & slow speed to highway speed robust WIM Scales & PC Mobile Weighing Systems. See the extensive list of ALL our product types, meeting the special needs of each customer.

Walz Scale open_in_new

Location: East Peoria, IL

Walz Scale is a leading global supplier and service support provider of heavy-duty truck & rail scales, volumetric load scanners, dimensional and precision weighing systems for use in transportation, agriculture, chemical, laboratory, aggregate, manufacturing, waste, recycling and mining applications. For over 54 years, Walz Scale has been providing the highest level of weighing products and local calibration and repair support to our customers.

Scale Systems open_in_new

Location: Norcross, GA

We have made it our goal to treat each and every customer like number one in order to keep them coming back to us for all of their industrial scale needs and also in hopes of turning first time customers into lifelong connections! Our skilled engineers will be able to assist you in find a product that will perfectly fit your needs. For more information on what we may be able to do for you visit our website today!

Brechbuhler Scales, Inc. open_in_new

Location: Canton, OH

Since 1929, Brechbuhler Scales has been a leader offering a wide variety of industrial scales such as balance scales, digital scales, truck scales, crane scales, floor scales, platform scales and more. We also provide rental scales from our large inventory and are ANSI 9002 registered.

Scales

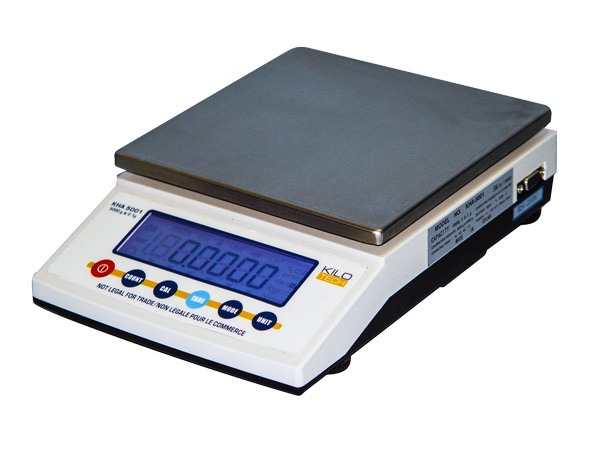

Scales can be small enough to measure tiny objects, but typically in bulk material handling applications, they are at least large enough to weigh a loaded pallet. Some industrial scales are large enough to weigh an entire loaded trailer or shipping container. Scales are made in many different forms, including: bench scales, hanging scales, and platform scales. A bench scale is raised up off of the ground by several inches or a few feet and may even be moved around a facility as needed. The raised stance of the scale makes it easier to load and unload small to medium sized loads. A platform scale or floor scale is level with the floor and typically has a large platform for weighing large bulk loads. A forklift or other vehicle can be used to move the weight directly onto and off of the scale. A hanging scale suspends loads in the air and gauges their weight based on the amount of gravitational force that they exert. Scales can have either digital or analog readings. While a scale with a meter and a needle that displays the weight of a load may be accurate, it is not as precise or as easy to read as a digital scale. Digital scales show decimals and make it possible to be highly precise during the weighing of bulk products. In any bulk operation, the most important consideration when investing in an industrial scale is the maximum weight that it is able to measure. Scales can range from a capacity of just a few grams to over 80,000 pounds. Knowing the needs of your application and choosing a scale accordingly will prevent technical errors and allow for the accuracy that your system needs. When bulk products are weighed on a scale, they are usually on a pallet or loaded into some kind of container. The weight of the container or pallet itself can be inputted into the scale so that the only material being measured is the bulk material. If distributors are being charged by weight, it is important that a bulk handler does not also charge them for the weight of the container. To determine the weight of a load, scales are built with hydraulics, balances, springs, or load cells. In more complex scales, a combination of these devices is used. In most industries, scales are subject to regulatory standards that have been established by the National Institute of Science and Technology. These standards ensure worker safety and accuracy for the measurement of bulk goods. In a bulk material handling system, scales can be placed near other equipment and loaded manually by workers, or they can be loaded and unloaded intermittently by automated machines. In these instances, the machines receive information from the scale that tells them when the load has reached the required weight.Bulk material handling systems in agriculture, food processing, pharmaceuticals, and more all use industrial scales to weigh products before they are packaged or shipped. Sometimes it is necessary to use scales to weigh small quantities that are then added to a larger mixture in a processing plant. Again, accuracy is key to maintain consistency and quality across bulk products in applications like these.

Floor Scale - PCE Americas, Inc.

Floor Scale - PCE Americas, Inc. Industrial Drive-Through Scale - PCE Americas, Inc.

Industrial Drive-Through Scale - PCE Americas, Inc.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services