One of the unique challenges of bulk material handling is that goods must be moved in massive quantities. Often, these materials are very heavy and they require mechanical assistance to be moved around, stored, and shipped.

Mollers North America Inc open_in_new

Location: Grand Rapids, MI

Moller North America is committed to customer satisfaction. Our line of products ranges from bagging, conveying, palletizing, to stretch-hooding, stretchwrapping and shrinkwrapping a variety of products. Contact us today to for all of your packing, palletizing, and protection needs.

American-Newlong, Inc. open_in_new

Location: Mooresville, IN

It is our goal at American-Newlong to create innovated bag packing and palletizing solutions. Our systems are ideal for industries including seed, feed, salt, minerals, aggregate products, pet food, chemicals and more. We take pride in saying that our palletizers are extremely energy efficient which saves money for our customers in the long run. This is made possible from superior technologies and high quality programming.

Applied Manufacturing Technologies open_in_new

Location: Orion, MI

AMT specializes in robotic integrated end of line packaging systems and machines. We excel at the design and manufacture of turnkey case packing and palletizing systems. Our engineering team is ready to work with your automation team or AS your automation team. We recognize and appreciate the trust you put in us as your integrator and proudly stake our reputation on every system we build.

TopTier Palletizers open_in_new

Location: Portland, OR

TopTier is the leader in innovation and value -- providing palletizing solutions with speed, flexibility, and dependability for 24/7 operations. Founded in 2003, TopTier installs floor and upper level infeed single automatic palletizers or systems integrated with existing conveyor and other material handling equipment. Both row-forming and robotic technologies from TopTier make palletizing reliable, easy, safe, and energy efficient. Contact us today for more information!

Chantland MHS open_in_new

Location: Dakota City, IA

Chantland-MHS material handling equipment improves customers’ efficiency, productivity & competitive position worldwide. Put experience since 1943 to work for you; choose from a line of bag fillers, conveyors, palletizers & complete systems. We specialize in bulk, bag, package & pallet conveyors; bag, box, drum & FIBC fillers; conventional and Fuji robotic bag palletizers, and system integration.

DePeuter Packaging Solutions, LLC open_in_new

Location: Houston, TX

DePeuter Packaging Solutions (DPPS) is a provider of end of line packaging equipment, including palletizers, depalletizers, single cell robotics, case packaging machines, conveyor systems, and totally integrated factory automation systems. From small single cell projects to complete turnkey systems, our team of experienced engineers and technicians will be available to assist with any application.

Eriez open_in_new

Location: Erie, PA

Our powerful magnetic palletizer and depalletizer can lift and position layers of steel cans at one time from a multi-layer stack, and can do it quickly without tumbling, jamming or can damage. Our palletizer/depalletizer magnets can be built in various sizes to fit the can stack configurations of your workplace. Choose Eriez for solutions to your palletizing needs.

Bagging & Palletizing

To reduce manual labor and increase efficiency, bulk material handlers use palletizers. A palletizer is a machine that can load and unload pallets before and after shipping or storage. Since pallets are a standard means of storing and transporting bulk products in many industries, a palletizer is a versatile solution. Before bulk materials are placed on pallets by a palletizer, they must be bagged or put in a container of some kind. Typically, other equipment is used to accomplish this, and then the loaded bag or container is placed on the pallet by the palletizer. If a bulk product is being bagged, the bag is usually filled by a machine that holds the bag as material is discharged into it. The palletizer may be underneath or beside this machine, and it is ready to accept the loaded bag on an empty pallet. Manufacturers of palletizing equipment make three different types of palletizers: low-level, high-level, and robotic. A low-level palletizer accepts packaged bulk goods at the ground level and moves them along a conveyor. A high-level palletizer is loaded from above. Usually, both of these types are fully automatic so that no manual intervention is necessary. A robotic palletizer is typically placed between a conveyor with incoming materials and a dispenser. The unit can actually pick up these materials and place them on a pallet before dispensing the pallet to another area. A robotic palletizer can be programmed to work with many different types of bulk products and has a high weight capacity. Adding a palletizer into a bulk material handling facility helps to further automate the system’s process and reduce the risk of injury or lost material during transfer. Palletizers are faster than manual labor, and there is less chance of human error causing an accident while materials are being loaded if a machine is used. Overall productivity, safety, and efficiency all benefit when a palletizer is installed. To improve safety and minimize the chance of damage to the equipment, many palletizing units have QuickSTOP collision sensors. These sensors detect any damage to the equipment and shut it down immediately before further damage occurs. Smartscan systems can also be added to palletizers to detect human movement near the equipment. If someone gets too close, the machine will automatically shut off. While palletizers are powered by an electric motor, some heavy duty ones may uses hydraulics to raise and lower loaded pallets. Bulk material handling systems in almost every industry use pallets to transport their goods after they have been processed, so palletizers are a common piece of equipment. Industries like agriculture, food processing, pharmaceuticals, and chemical engineering all make use of palletizers to load products in a container or bag onto a pallet before shipping.Palletizers come in a range of types and sizes, so the cost varies. However, the upfront cost of a palletizing unit is usually significant, but returns can quickly be seen as the volume of bulk material processed increases. Most bulk material handling facilities easily recoup the investment that they make in a palletizing unit.

High-Level Palletizer - Columbia Machine, Inc.

High-Level Palletizer - Columbia Machine, Inc. Robotic Palletizer - American-Newlong, Inc.

Robotic Palletizer - American-Newlong, Inc.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

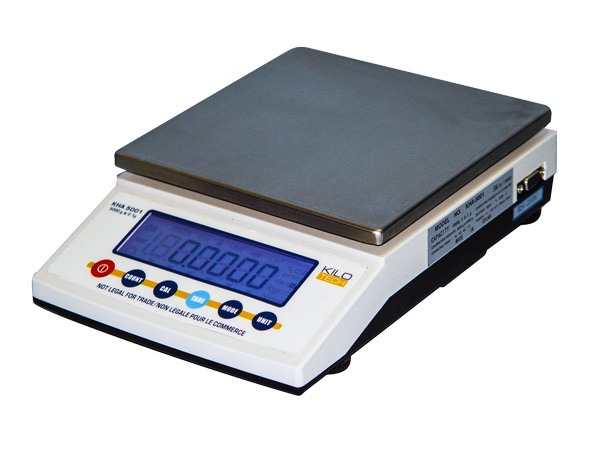

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services