Dust Collection

Fine particles can create a lot of dust when they are being handled, and since some materials are harmful when ingested, this can be very dangerous to anyone working in the area. Not only can the dust be harmful, but it can create a very dirty environment where cleanliness standards are impossible to maintain.

Scientific Dust Collectors open_in_new

Location: Alsip, IL

Scientific Dust Collectors (SDC) began in 1981 when our first patent for improving filter cleaning was issued. Since then, SDC has been issued a number of additional related patents for improvements in dust collector cleaning technologies including our patented nozzle-based cleaning system which is superior to other collectors. Combined with our High Side Inlets, Wide Filter Spacing, and Inlet Baffling, we are able to guarantee performance, efficiency, and filter life. If you want the best, please consider SDC.

Griffin Filters open_in_new

Location: Liverpool, NY

Griffin Filters is a trusted and dedicated leading manufacturer in the dust collector industry. We offer a wide selection of dust collectors with customization options available in order to serve various industries. Our experts are committed to manufacturing high-quality dust collectors that fit our customers' needs at competitive prices. Since its start in 1950, Griffin Filters has been setting industry standards in the dust collecting industry.

Clean Air Technology Solutions open_in_new

Location: Hopkinsville, KY

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our dust collector systems. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

RoboVent open_in_new

Location: Sterling Heights, MI

Ever since our inception in 1989, Robovent has been a leader in the manufacturing and design of ventilation and filtration systems. We have experience coming up with solutions to protect our customers from a wide range of dust, including aluminum dust, cast iron grinding dust, fertilizer dust, and more. Industries we serve include automotive, military, construction, medical, and aerospace. For a complete list of our services and capabilities, visit our website or call Robovent today!

Environmental Clean Air Company open_in_new

Location: Loganville, GA

Environmental Clean Air Company provides clean air solutions for a wide variety of indoor air quality problems. We offer a wide selection of dust collectors, mist collectors, welding booths, work containment booths, cyclones, electrostatic filters, air cleaning and filtration equipment to meet the demands of today's Industry.

Camfil APC open_in_new

Location: Jonesboro, AR

Here at Camfil APC, we understand that during the manufacturing process dust and other pollutants are introduced to the air. In order to combat this we have a wide variety of dust collecting systems that include, but are not limited to, our Gold Series® Industrial Dust Collector, Quad Pulse Package, and our Zephyr III®. We service the food & beverage, chemical processing, pharmaceutical, thermal spray, and the mining industries. To learn more about Camfil APC, call us today!

Midwest Finishing Systems, Inc. open_in_new

Location: Hartland, WI

Our dust collecting systems are designed to eliminate respirable airborne contaminants from the work environment. We believe that eliminating airborne contamination in the workspace can lead to better employee performance and a lower rate of absenteeism. Therefore, we focus on excellence and customer satisfaction and will handle your unique dust collection challenge.

Besides the obvious concerns of harm to workers and cloudy air, many industries also run the risk of being the cause of pollution. Some bulk materials can be harmful to the environment if handled incorrectly, so many industries have regulatory boards or bylaws in place to enforce the use of air pollution control systems. Facilities that do not use these systems can be charged and run the risk of doing serious damage to the environment.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

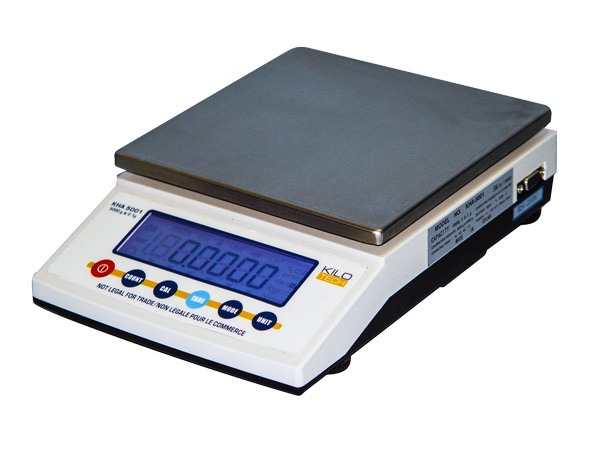

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services