Load cells are used in bulk material handling systems to gauge the weight and force of a load of bulk material. The purpose of this ability is to test mechanical systems and monitor their output during production times.

Strainsert Company open_in_new

Location: West Conshohocken, PA

Just a few of the different types of load cells that we offer are universal load cells, compression load cells, metric universal load cells, fatigue rated load cells and many others. Our products serve many diverse industries including aerospace, automotive and industrial as well as a broad variety of others. We are dedicated to working closely with you to come up with the exact product that you need. Visit our website today to learn more!

Load Cell Central open_in_new

Location: Milan, PA

Since 1985, Load Cell Central has been a leading manufacturer in the load cell industry. We offer a wide selection of load cells with customization options available to better fit the needs of our customers. Our expert team works alongside our customers from start to finish and continues to be available for after-sale support. Load Cell Central prides itself on our attention to detail and high-quality products.

TyTek Industries open_in_new

Location: West Chester, OH

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

Anyload Weigh & Measure Inc. open_in_new

Location: East Hanover, NJ

Anyload has been in business for over 20 years. Anyload is experienced in the design and production of high quality standard load cells, specialty load cells, weigh modules, indicators, scales for commercial and industrial applications, and wide varieties of weighing components.

Coti Global Sensors open_in_new

Location: Harvest, AL

At Coti Global Sensors, we are dedicated to providing top-of-the-line load cell solutions and comprehensive services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted authority in load cell manufacturing, renowned for our commitment to quality, reliability, and customer satisfaction.

Load Cells

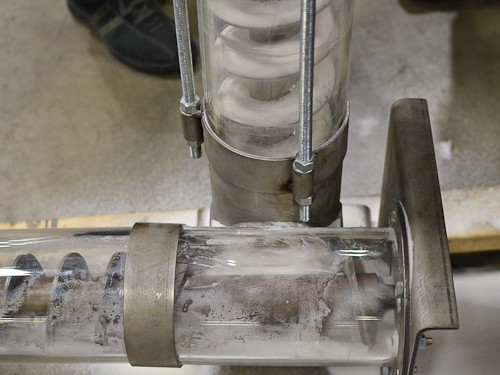

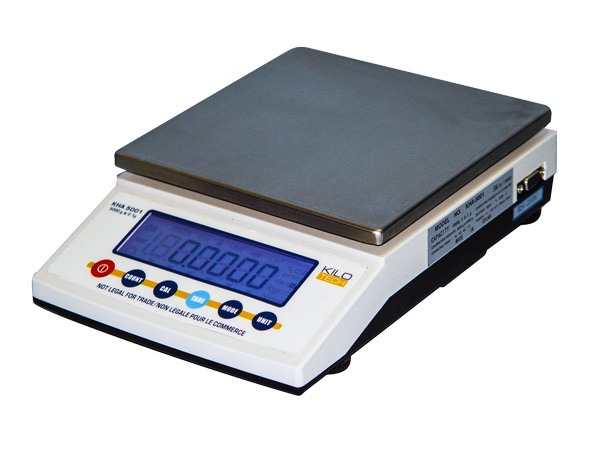

Load cells are particularly important for maintaining the accuracy of the industrial scales that are used to weight bulk products. Compression and tension are the most common force measurements made using load cells. Many load cells are built with an internal strain gauge, a small device that can measure how much strain is put on an object using electrical signals. Force gauges do the same thing but for push-pull testing or measurement of flow. The flow of liquid or viscous bulk materials can be measured by pressure sensors. This is useful to determine the rate and force of flow through a bulk system for optimization and efficiency purposes. Digital load cells are the most popular and the most easy way to access the information that sensors pick up during operation. In food processing facilities, load cells play an important role in measuring ingredients before they are entered into a mixture. This precision is critical to the on-going quality of a product. Perhaps the most important function of a load cell is to determine the exact weight of loads, like a loaded pallet. When bulk processors ship their goods, they need to know the precise weight for logistics and billing reasons. Load cells provide readings that are accurate within 0.25%, which is extremely precise for applications where a single load may weigh several tons. So how exactly does a load cell work? A load cell is designed to convert mechanical stress into electrical energy. Information is received in this way and sent to a data collection system in the device. This is then turned into an output or reading that an operator can see as an item is placed on a scale or material runs through a tube. Analog load cells still exists, but they have been largely surpassed by digital load cells because they are more accurate and easier to read. In applications where a load cell is used to shut off equipment, the cell is designed to sound an alarm when a predetermined event or set of criteria is observed. Load cells can be fitted with multiple gauges. The more gauges, the more sensitive the cell will be to changes and the more accurate its measurements will be. Necessary accuracy, type of force, and response time are among the most important factors that must be considered when a cell is being designed for an application. Load cells are used in equipment at bulk material handling facilities in mining, food processing, pharmaceuticals, oil & gas, agriculture, and other industries. Although a load cell is very small, it has a huge impact on the efficiency and cost-effectiveness of major operations.Some manufacturers specialize in load cell production and work with industry experts to create devices that perform specifically for certain materials or applications. Others are more general and can be used in many different bulk handling capacities.

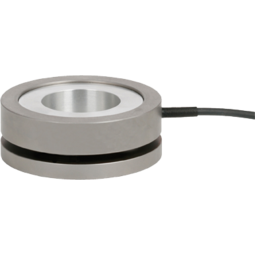

Compression Pancake Load Cell - tecsis LP

Compression Pancake Load Cell - tecsis LP Donut Load Cell - tecsis LP

Donut Load Cell - tecsis LP

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services