Vacuum cleaners are cleaning machines that use suction to collect dirt, dust, waste products from industrial processes, and other kinds of debris for disposal, recycling, or reuse

VAC-U-MAX open_in_new

Location: Belleville, NJ

We are vacuum experts, both for vacuum cleaners and vacuum systems for manufacturing needs. We will create custom systems that will help you reach your industry goals- no matter what they our. Our systems offer budget protection that is built to last. Find out more when you contact us by phone or email today! We would love to start serving you right away!

Multi-Vac Inc. open_in_new

Location: Union Grove, WI

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more. With our many years of experience, you can expect quality products and excellent service. Please call or visit our website today for more information.

Delfin Industrial Vacuums open_in_new

Location: Plymouth, MN

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and high-quality products to ensure their needs are met.

Legends Equipment Company open_in_new

Location: Dayton, KY

At Legends Equipment Company, we take pride in our custom-engineered central vacuum systems designed for heavy-duty industrial applications. Our vacuum cleaners are a testament to our commitment to excellence in providing efficient and powerful solutions for challenging environments. With a focus on innovation and reliability, we understand the unique demands of industrial settings, and our vacuum cleaners are crafted to meet and exceed those expectations.

Fast-Vac™ open_in_new

Location: Union Grove, WI

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. Whether you need cleaning or maintaining, recycling, non-destructively excavating, or improving air quality, our industrial vacuum loaders offers high power suction to convey solids, liquids, sludges or slurries. Call or visit our website to learn more!

Bortek Industries, Inc. open_in_new

Location: Mechanicsburg, PA

Being a world leader in the industrial vacuum arena defines Bortek. We offer litter vacuums, industrial vacuums and scrubbers, HEPA vacuums, portable vacuums and more. Our vacuum cleaners are used in industrial and commercial applications. Our industrial specialty vacuums are at your service.

Goodway Technologies Corporation open_in_new

Location: Stamford, CT

Goodway Technologies Corporation specializes in industrial, commercial and wet/dry vacuum cleaners. We provide excellent customer service and support in order to help each customer choose the best industrial vacuum cleaner, vacuum cleaner system or other vacuum product to suit exacting specifications.

Vacuum Cleaners

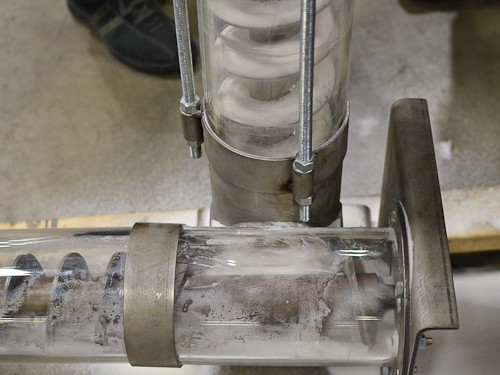

In many bulk material handling settings, some materials are lost during processing or transfer. An industrial vacuum cleaner can be used to clean up these materials and even reclaim them for processing at another time. Excess bulk solids can build up quickly in a busy industrial facility, so a strong high-capacity vacuum cleaner is the best way to keep things clean. Vacuuming also eliminates dust and other harmful toxins that may be present in the air and hazardous to human health. Industrial vacuums come in many types and can be configured to almost any type of media; from wet to dry bulk materials and more. In some cases where contamination is not a concern, these materials can be gathered up and entered into the bulk material handling system again. This reduces waste and improves the overall efficiency of the process. More advanced industrial vacuums are built with HEPA filters so that both large and small particles can be removed from a facility. Essentially, a vacuum is an area from which air has been removed. This drastic reduction in pressure causes the more highly pressurized air surrounding the vacuum to rush into it with great force. Vacuum cleaners are able to create an artificial vacuum with low air pressure in order to collect debris. All vacuums cleaners are configured differently and some create lower pressure than others. However, in all vacuum cleaners the same basic principle applies and dust or dirt is quickly drawn in. There are several different types of industrial vacuum cleaners that can be used in bulk material handling systems: continuous bagging vacuum cleaners, air powered vacuum cleaners, and continuous duty vacuum cleaners. Continuous bagging vacuum cleaners are designed to deal with dusty debris. These systems are equipped with closed bags that capture and confine dust so that it does not spread through a facility. The vacuum can run continuously to capture particles as bulk materials are being conveyed or processed. Air powered vacuum cleaners make use of forced air to gather materials. The do not require electricity or generate heat, so they are very safe to operate in a facility that handles hazardous materials. Finally, continuous duty vacuum cleaners are built to work around the clock in tough environments where constant vacuuming is a necessity. Continuous duty vacuums are usually used when material recovery is a priority since they can operate for as long as all of the other equipment is running. In small to medium sized bulk material handling operations, industrial vacuum cleaners may be portable so that they can be moved throughout the facility as needed. In larger bulk material handling facilities, the vacuum may be placed in a stationary position somewhere in the production line, or there may be several vacuum units to capture all of the dust and debris.Central vacuum cleaning systems are also an option for some bulk material handling facilities. These systems have a central chamber that is connected to various outlets in the facility via ductwork. Hoses can be moved around and inserted into the outlets which then transport the debris to the chamber. The container of a central vacuum system can be emptied periodically and stored out of sight for a more efficient use of space.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

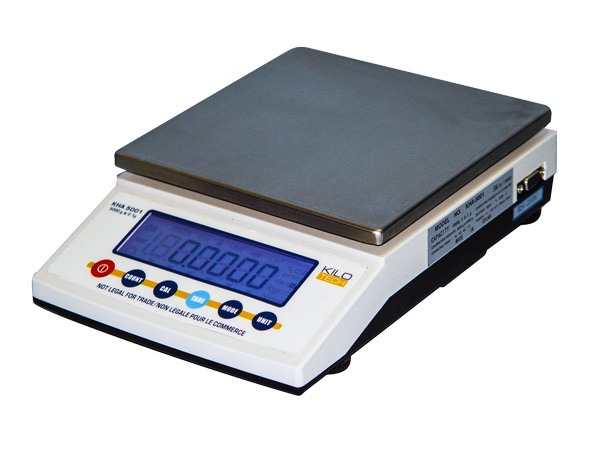

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services