Hoppers

Hoppers are typically manufactured using sheets of steel, due to its durability and the ease of manufacturing.

The steel is generally formed into a conical or wedge-like shape to facilitate the movement of materials toward the outlet at the bottom of the hopper.

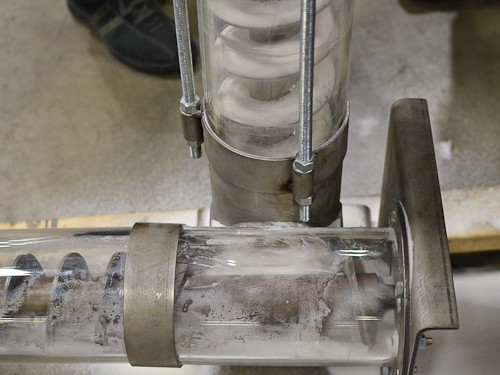

At the outlet port, the hopper can be fitted with a variety of different components, depending on the requirements of a particular application. Some simply have a sealable port which can be opened to quickly dispense large quantities of materials.

Other hoppers may be equipped with valves for more controlled distribution of the contents. For example, hoppers used to feed materials into pneumatic conveying systems commonly use rotary valves to gradually feed materials into the conveying stream. Still other hoppers may use an auger to discharge material.

These containment products are incredibly important in many different bulk material handling processes because they provide a means for controlling the dispensing of bulk products.

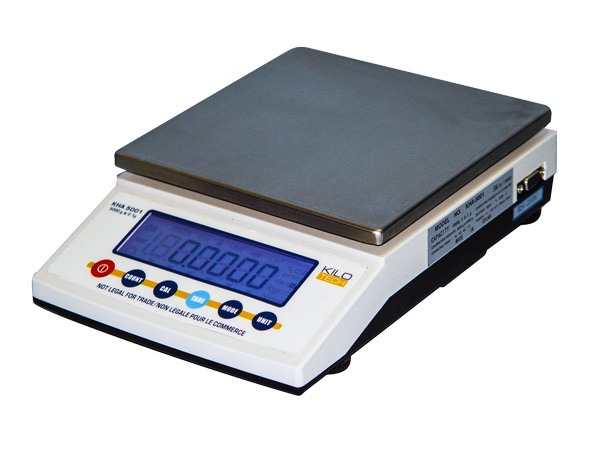

For weigh and batching applications, they can be outfitted with sensors to track how much material they contain which is incredibly important for ensuring that a particular batch has the right blend of ingredients and the appropriate quantity of each ingredient.

They also provide flow control for conveying systems. With the appropriate components, a hopper can help keep conveyors from being overloaded, which can lead to a variety of problematic consequences.

In fact, these products are so vital to bulk material handling that they are often built into or integrated into other bulk material handling products as standard.

All in all, when it comes to bulk material handling applications, hoppers are a crucial component for material flow and control.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services