Separation Equipment

While this can be accomplished manually, it is much more efficient when separation equipment is used to sort bulk material. Some of the most common pieces of material separation equipment for bulk applications are listed and described below.

Magnetic Separators

Magnetic separators are important in the mining industry where they can be use to separate ferrous and non-ferrous metals. A magnetic separator can prevent harmful bits of metal from entering machinery further down the line, and they can remove impure or unwanted materials from a stream. The magnets pull out the unwanted material as the bulk materials pass by on a conveyor. A permanent magnetic separator does not need any electric power to operate. These mechanisms can last for a long time without requiring maintenance or losing a significant amount of strength. More powerful industrial magnetic separators may use coils and direct currents to create a stronger magnetic field.

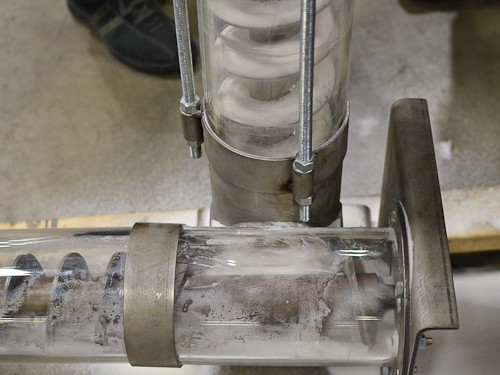

Air Separators

To make sure that volume measurements in a bulk handling system are accurate, an air separator is used. As bulk material passes through the chamber of an air separator, air or gases are removed from the material. Vacuum technology is commonly used to suck all of the air out of a confined space so that the only remaining substance is the bulk material itself. An air separator can easily be integrated into a pneumatic conveying system as either side of the unit can be connected to pipes or tubes.

Flotation Separators

Flotation separators use the principle of buoyancy to separate bulk materials. Water is added to a large tank, and the water’s density can be altered using certain additives that help to create the desired effect. Next, the material is added to the water. As a result, only materials with a density greater than that of the water will sink to the bottom of the tank as the rest remain floating at the surface. Mechanical arms scoop up the floating materials and move them along to the next part of the system. Flotation separation is an efficient way to separate minerals from other particles and debris. The debris that has fallen to the bottom of the tank can be ejected through a discharge hatch or periodically cleaned out of the tank from above.

Materials separation equipment is used to sort particles in bulk material handling systems in industries that range from agriculture to pharmaceuticals to food processing, mining and beyond. With machines that can separate high volumes at such a rapid rate, bulk material handlers in some industries are able to process more materials in a day than they could by way of manual labor in a week. Technological advancements like this are what help to make bulk material operations so large and efficient today and enhance the many possibilities of bulk handling.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

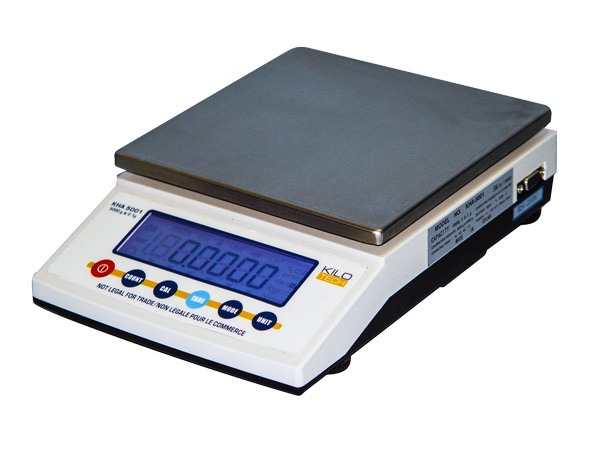

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services