A vibratory screener is a stationary or portable piece of equipment in a bulk material handling facility that removes unwanted materials from a batch using vibrations.

Eriez open_in_new

Location: Erie, PA

ERIEZ is a global manufacturer of an entire range of vibratory feeders and related machinery. We serve all the process industries, including food, chemical, pharmaceutical, ceramics, glass, packaging, metalworking, minerals processing and others. We also offer feeding machines so that all of your needs can be met. Please contact our company for a quote today!

Rodix, Inc. open_in_new

Location: Rockford, IL

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC open_in_new

Location: Newberg, OR

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

Hoosier Feeder open_in_new

Location: Knightstown, IN

If you are in need of quality vibratory feeders, we can help you out! At Hoosier Feeder, our philosophy is simple. We aim to put our customers first, get their requests right on the first try, communicate with them every step of the way, and deliver their products on time. We have experience working with a wide range of industries such as pharmaceutical, automotive, and food and beverage. For more information, please call or visit our website!

M & S Automated Feeding Systems, Inc. open_in_new

Location: Burnsville, MN

M&S Automated Feeding Systems creates parts feeders built and tested to each customer’s specific application. Fully equipped to design, fabricate and service a complete range of quality feeding equipment and specialized parts handling systems, including vibratory controls, conveyors, custom mechanisms, centrifugal feeder bowls, hoppers, vibratory inline feeders, sealing and vision systems.

Vibratory Screeners

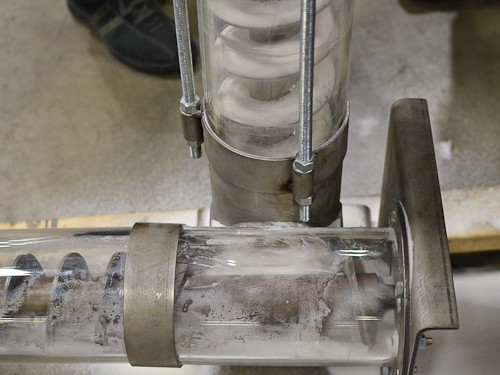

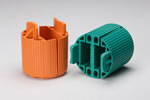

Materials are moved over a screen and vibrated in such a way that only the desired particles fall through, while larger debris is caught by the screen. If there is unwanted liquid in the material, a sieve type vibratory screener is used to separate the solids from the liquid. Sometimes the waste is recycled after cleaning if it can be broken down into a useable form. Vibratory screeners are not just used to separate materials; they are also important for classifying bulk materials by size. The larger or smaller materials that are removed may not necessarily be unwanted, they might just need to be classified and packaged differently. Plastic pellets can be sized and screened using a vibratory feeder during the handling process. Although there is a wide variety of vibratory screening machines available on the market, some unique handling applications require customized screeners. Specialized manufacturers offer custom-built vibratory screeners based on the dimensions and processing needs of your facility. There are a number of considerations that need to be made when you are purchasing a piece of vibratory screening equipment, or when you are working with a team of engineers to design one. First, you need to determine what vibration frequency works best for the material that you will be handling. This can be determined by testing with a vibratory screener at various frequencies to find the optimal setting. You will also need to find out how large the screen should be and what size the reservoir needs to be. The reservoir holds material or feeds it into the next stage of the process. The size of the screen and the reservoir below it will depend on the scale of the bulk material operation.However, even in a large processing facility, the vibratory screener cannot be too large or it will not screen material as thoroughly.

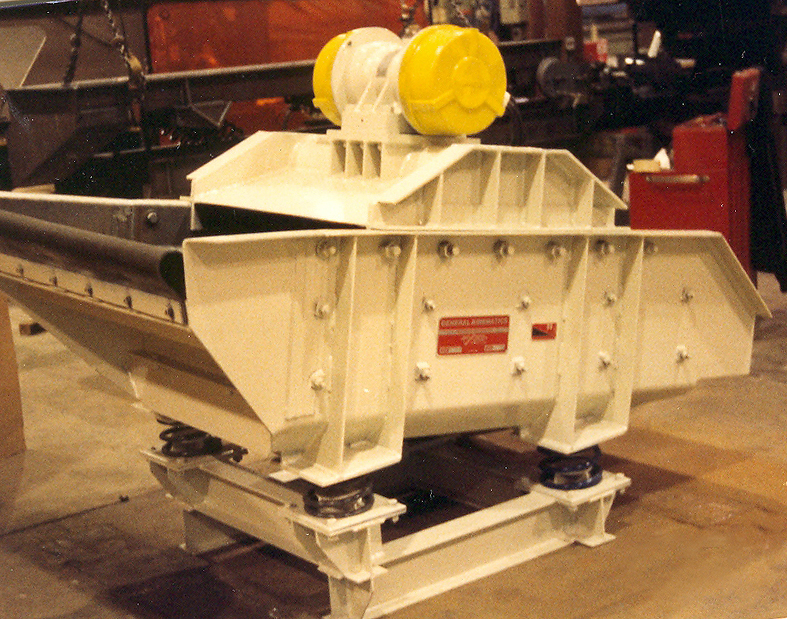

Direct Drive Vibrating Screen - General Kinematics

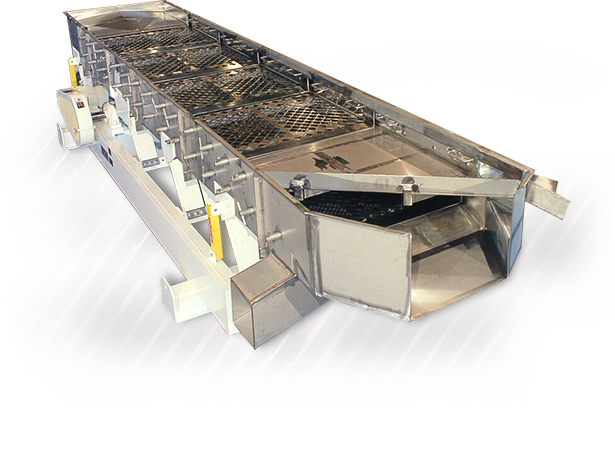

Direct Drive Vibrating Screen - General Kinematics Vibratory Screener - Carrier Vibrating Equipment, Inc.

Vibratory Screener - Carrier Vibrating Equipment, Inc.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

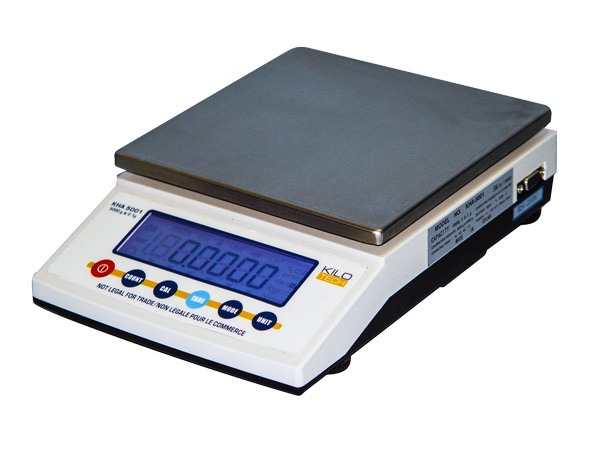

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services