Belt conveyors are a type of conveyor system, which are systems that move, or convey, different types of materials from one point to another and/or through various stages of processing. Conveyor systems in general use a number of different means to move goods and materials. These different means include floor chain conveyors, overhead chain conveyors and more.

mk North America, Inc. open_in_new

Location: Bloomfield, CT

mk North America, Inc. offers the widest variety of conveyors in the industry. Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. At mk we believe in offering not only a better product, but also a better solution – which is why we will work with you to ensure your unique application is matched with the best possible conveyor solution. Belt, roller, chain, timing belt and many other conveyor types are available.

SRSI - Slate River Systems Inc open_in_new

Location: Dallas, TX

At Slate River Systems Inc, we take pride in our expertise as innovators in the field of conveyor systems. With years of collective experience, our team is committed to delivering cutting-edge solutions tailored to meet the diverse needs of our clients. Our conveyor systems are engineered to optimize efficiency and streamline material handling processes across various industries.

Redline Systems, Inc. open_in_new

Location: Clearfield, UT

Redline Systems, Inc. is a leading provider of innovative conveyor solutions. They offer various conveyor types, including portable belt conveyors, incline conveyors, horizontal conveyors, stainless conveyors, and more. Experience the difference with Redline Systems, where innovation meets reliability in conveyor technology.

Impact Automation, Inc. open_in_new

Location: Columbia, MA

Impact Automation stands as a prominent force in the field of automation, specializing in the design and implementation of advanced conveying systems tailored for diverse manufacturing processes. With a focus on efficiency, precision, and adaptability, we offer a comprehensive product range that includes sorter feed systems, sorter solutions, traditional conveyors, and plastic belt conveyors.

Spiroflow Systems, Inc. open_in_new

Location: Monroe, NC

Spiroflow offers a complete range of mechanical conveying solutions in the industry. The staff at Spiroflow can recommend the best method to meet your conveying needs. We are known as an early inventor of the flexible screw conveyor, and are now offering other products and services such as mechanical conveyors, cable drag conveyors, chain drag conveyors, and pneumatic conveyors.

Vecoplan, LLC open_in_new

Location: Archdale, NC

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Belt conveyors, which are the most widely used type of conveyor system, use a wide polymer or rubber belt wrapped around two or more uni-directional pulleys that rotate it, in order to convey goods and parts of all shapes and sizes. They are used in a variety of industries, including industrial manufacturing, retail manufacturing, pharmaceuticals, food and beverage processing, defense, paper, aerospace and automotive.

Benefits of Belt Conveyors

From airport baggage handling, to assembly lines, to postal sorting, to the transport of humans along moving sidewalks or escalators, to the transport of materials like grain, sand, salt, coal and ore, the unique uses of belt conveyors are nearly endless. They reduce labor, allow for the rapid conveyance of large volumes of materials and save space. In addition, they can be installed nearly anywhere and they can move loads of all shapes and sizes, no matter how irregular. On top of that, they are much safer than moving machines like forklifts. The choice to purchase a belt conveyor is an easy one. One who does so, however, should pay attention to some safety regulations. In the United States specifically, he or she must make sure that the system is configured and installed in such a way that it adheres to the regulations of the Occupational Safety and Health Administration (OSHA). He or she should also take the time to educate workers on the proper protocol for working with the system. For the best results, one should call an experienced belt conveyor manufacturer.

Design of Belt Conveyors

The belt of a belt conveyor consists of one or more layers of material, such as the aforementioned polymer, PVC or something else. First, the belt is supported by an over layer called a cover and an under layer known, known as a carcass. While the cover is typically made of polymers, combination plastics or rubber, it can also be made of more unusual materials, like silicon, which conveys heat, or gum rubber, which provides traction. The carcass is made of plastic web, polyester, nylon, cotton or mesh. It provides the belt with linear length and shape. Typically, one or all of the belt conveyor pulleys are powered by an electric motor, linked via a sprocket and chain; these pulleys are known as drive pulleys. The chain is wrapped around the sprocket or sprockets, connecting the drive pulley and motor and, in doing so, the motor is able to power the drive pulley’s rotation. Any pulleys that are not motor-powered are called idlers. To regulate the speed of pulley rotation, a speed reducer is also connected to the motor, this time by a "c" face coupling or a v-belt. Once assembled, both the speed reducer and the motor are stored underneath the conveyor bed. Said conveyor bed may be either a solid metal frame bed or a roller bed. The latter is selected for heavy-duty applications, where it provides some friction reduction and stress relief. Note that some belt conveyors use tapered rollers and curved belting in order to achieve curves for going around corners. Sometimes, a belt conveyor can be much more simple, functioning as a slide and controlled by gravity.

Types of Belt Conveyors

These material handling apparatuses are generally divided into two main groups: polyurethane, or PVC/Pu conveyors, and modular belt conveyors. Since polyurethane is a food grade polymer, PVC/Pu belt conveyors are frequently used for food processing and pharmaceutical applications. Modular conveyor belts run on guides and do not rely on tracking devices. They are easier to maintain and, when compared to the former belt conveyor style, have superior durability. While a better make, they are slightly more expensive than PVC belt conveyors, and so do not necessarily enjoy vast popularity. Other types of belt conveyors include incline belt conveyors, enclosed belt conveyors, steel belt conveyors, portable belt conveyors and sandwich belt conveyors. Other types of conveyor systems in general include: heavy duty rear conveyor systems, spiral conveyor systems, vibrating conveyor systems, gravity skatewheel conveyor systems, gravity conveyor systems, electric track vehicle systems, drag conveyor systems, vertical conveyor systems, flexible conveyor systems and pneumatic conveyor systems.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

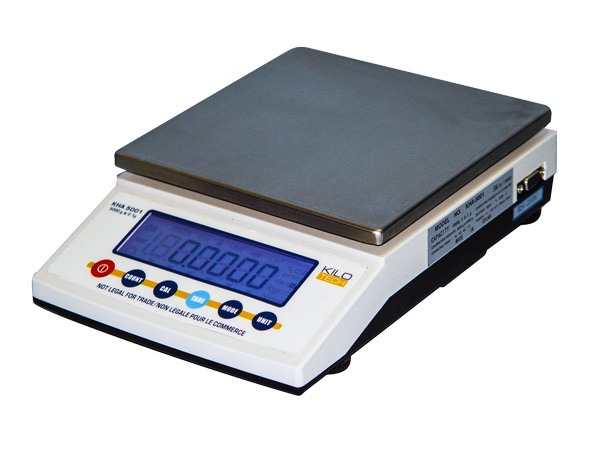

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services