Blowers are devices with a series of spinning blades that are used to generate airflow in a variety of applications. Blowers are important to almost all bulk handling systems because they can be used not only with dry bulk goods but also to power pneumatic conveyors by creating pressure changes for material transfer. An appropriately sized blower can be used in a pneumatic conveyor (large or small) to transport materials through a bulk handling system.Blowers for bulk material handling systems come in two main types: axial blowers and centrifugal blowers. Axial blowers are built with several curved blades that spin on an axis at high speeds.

National Turbine Corporation open_in_new

Location: Syracuse, NY

Since 1991, National Turbine Corporation has been a blower manufacturer, bringing you quality multi stage blowers for use in industrial applications. Our employees have over 160 years of combined engineering and manufacturing knowledge. From concept to final product we provide you with the right product and accessories to meet the requirements of any system.

AirPro Fan & Blower Company open_in_new

Location: Rhinelander, WI

#1 Most Reliable Fan Manufacturer. Thousands of customers depend on AirPro fans to keep their operations going, and that's why we build the highest quality fans, prioritize on-time delivery, and offer a 3-year warranty on all products! Founded in 2002, AirPro is privately held and 100% Employee-Owned. With headquarters and manufacturing facilities in Rhinelander, Wisconsin, we offer centrifugal fans for process air applications in North America and around the world.

The New York Blower Company open_in_new

Location: Willowbrook, IL

Since 1889, The New York Blower Company (nyb) has been a turn-key provider of catalog and custom fans, blowers and ventilation systems. We provide the design, manufacture, installation, maintenance, repair and rebuild of nyb and competitor products. We are constantly expanding, with a worldwide presence of over 200 representatives, and the opening of our fifth manufacturing facility in the US in 2022. Visit us at www.nyb.com/findmysolution/ to request more information today.

Kooltronic, Inc. open_in_new

Location: Pennington, NJ

At Kooltronic, we have established ourselves as a leading manufacturer specializing in a comprehensive array of blowers tailored to meet various industrial requirements. Our expansive product line encompasses high-pressure air blowers, centrifugal blowers, impeller blowers, and high-pressure radial blowers, showcasing our proficiency and versatility in the field.

Sterling Blower open_in_new

Location: Forest, VA

At Sterling Blower, we take pride in our exceptional line of blower products that cater to a diverse range of industries. With decades of expertise, we have honed our craftsmanship to deliver top-notch blowers designed for optimal performance and efficiency. Our commitment to quality is evident in every product we offer, ensuring that each blower meets the highest standards of durability and reliability.

Republic Manufacturing open_in_new

Location: Dallas, TX

Republic Manufacturing offers industries a wide array of air moving solutions. Currently, our product range includes blowers, vacuum pumps, compressors, air knives, motors, and systems. While many products are available for immediate shipment, Republic's in-house staff of engineers can design custom options to meet specifications necessary utilizing state-of-the-art software and machinery. We will be happy to assist you to help determine what equipment best fits your needs.

Hartzell Air Movement open_in_new

Location: Piqua, OH

If you are looking for a solution solving industrial blower supplier, look to Hartzell Air Movement. We have been an industrial blower manufacturer for 75 years & carry products such as air blowers, exhaust fans, industrial fans, centrifugal blowers & high velocity fans for the air moving community. At Hartzell, our mission is to provide high quality & reliable industrial air moving equipment & services.

In some cases, manufacturers create entire bulk material handling systems, so they know exactly which blowers will be best in a particular facility. From plastics to chemical handling to food processing and beyond, most industries would not be able to handle bulk materials efficiently without blowers.

Centrifugal Blower - National Turbine Corporation

Centrifugal Blower - National Turbine Corporation Millenium™ Series Air Handling Blower - National Turbine Corporation

Millenium™ Series Air Handling Blower - National Turbine Corporation

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

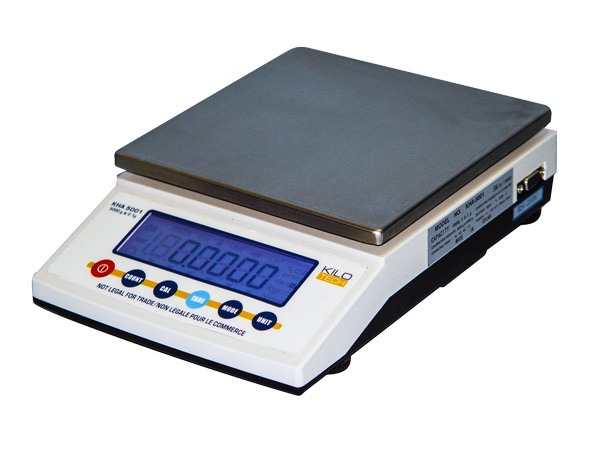

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services