Tanks made of stainless steel are used to hold and store a variety of bulk substances. They are usually cylindrical, like drums, but their shape and orientation often varies-tanks are either horizontal or vertical and may hold anything from 1 gallon to millions of gallons.

Frain Industries, Inc. open_in_new

Location: Carol Stream, IL

Here at Frain Industries, Inc. we offer an extensive line of stainless steel tanks. These tanks come in a wide range of shapes and sizes based on their application. Our tank sizes range from 5 gallons to 10,000 gallons and these tanks can be customized to meet your application needs. Our tanks can be designed in a number of different styles including: jacketed, single wall, vertical, horizontal, cone bottom, dish bottom, insulated and much more. Contact us today to learn more!

G & F Manufacturing Company, Inc. open_in_new

Location: Oak Lawn, IL

For 50 years G & F Manufacturing has been a leading quality stainless steel tank manufacturer for many industries, including pharmaceutical, food & beverage. Their storage containers offer quality workmanship & durability. G & F offers standard & custom vessels for storage & mixing which include open & closed top vertical & horizontal storage & mixing tanks with capacities to 10,000 gallons. Give us a call to learn more!

Rexarc International open_in_new

Location: West Alexandria, OH

Rexarc provides fabrication of custom stainless steel and carbon pressure vessels, between 500 and 5,000 psi. Our proven process and facility allow smooth throughput of vessels up to 8’ in diameter and/or 15-tons in weight. Rexarc’s traditions of customization, communication, and commitment to on-time delivery of products has span nearly 100-years of family leadership. Our customers know that we were here yesterday, we are here today, and we will be here tomorrow.

Weston & Associates open_in_new

Location: Massillon, OH

At Weston & Associates, we take pride in our extensive range of stainless steel tanks, meticulously designed and crafted to cater to a myriad of industries. Our tanks are not just products; they are a testament to our relentless pursuit of quality and functionality. We understand that each client is unique, and our diverse portfolio of tanks reflects our adaptability in customizing solutions that align seamlessly with individual requirements.

True-Blue Welding and Fabrication LLC open_in_new

Location: Minooka, IL

At True-Blue Welding and Fabrication LLC, we pride ourselves on our expertise in crafting high-quality stainless steel tanks. Our journey is defined by a relentless pursuit of perfection and a commitment to meeting the diverse needs of our clients. Join countless satisfied clients who have entrusted us with their most demanding projects and experience the True-Blue difference today.

Badger Fabrication, Inc. open_in_new

Location: Sauk City, WI

Badger Fabrication is a family owned, custom stainless steel and waterjet cutting fabricator. We serve the food, diary and construction industry. Our state-of-the-art capabilities and craftsmanship will provide the quality, design and performance your application requires. We can provide finished products such as single shell tanks, mixers, enclosures, sanitary fittings, conduit hangers and more.

SteelCraft Industries open_in_new

Location: Kitchener, ON

We offer a full range of stainless steel tanks such as vertical single wall tanks, process columns, portable mix tanks, cooking & pasteurizing kettle, specialty tanks, and more. We are committed to assisting you with finding a tank that meets your needs and these reliable products are very affordable.

Stainless Steel Tanks

Stainless steel is chosen because of its corrosion resistance, which makes it useful for the storage of hazardous substances, resistance to high temperatures, and strength as well as the ease in which it can be manufactured and cleaned. Manufacturers of stainless steel tanks supply numerous industries where bulk material is handled, including agricultural, food processing, medical, and chemical management. They are commonly used where hygiene and corrosion are concerns. They are often used in the agricultural industry where they usually store animal feed and crops, in the pharmaceutical industry where they are used to store powders and chemicals, in the food industry storing bulk ingredients, and many other industries and applications. Stainless steel has good thermal conductivity and thermal expansion rate, which is key to tanks of any sort, and particularly useful in the case of pressure vessels. There are many different types of stainless tanks that differ in properties depending on their applications. SS tanks always contain openings called manways, where contents are poured or accessed. Stainless steel tanks are thin-walled constructions manufactured through a rolling process or welding. Although stainless steel is strong, it is vulnerable to buckling when the material is thin. Stainless steel tanks are most susceptible to damage during construction, transportation, and installation. The contents of full stainless steel tanks actually aid its stability. The shape of the tank is dependent on its diameter or height and the efficient use of material. Stainless steel tank manufacturers can make the ends of their products flat or in the shape of a dome or cone. In determining the size that a tank needs to be, consider how much extra volume should be included to cover for future process needs and also consider how the tank will be filled and discharged. The industrial applications where stainless steel tanks are utilized determine tank properties such as size, shape, and orientation. They are often vertical silos and horizontal or vertical storage tanks.Stainless steel is the material of choice for many industries because it is easily temperature controlled, cleaned, and sterilized. They must adhere to strict FDA, USDA and 3-A standards for health reasons. Tanks used to house foods are cleaned every time they are emptied and must maintain certain temperatures if they are holding perishable food items.

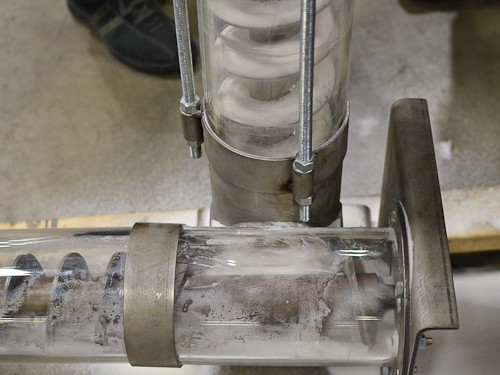

Single Wall Stainless Steel Tank - Frain Industries, Inc.

Single Wall Stainless Steel Tank - Frain Industries, Inc.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

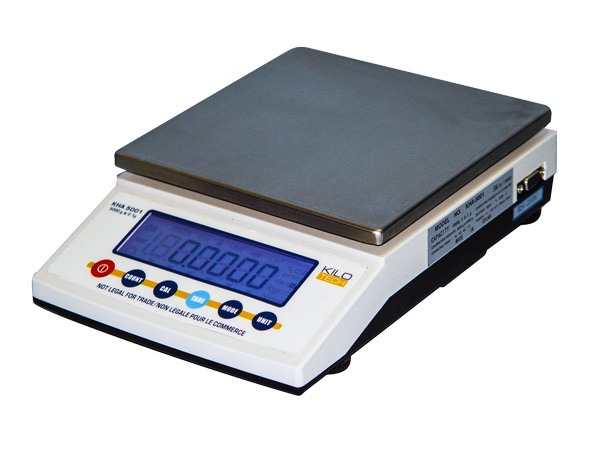

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services