Unload

Loading and unloading are both important steps in bulk material handling systems, and they require special machines. Because bulk materials are so heavy and need to be moved in high volumes, loading and unloading needs to happen quickly using heavy duty equipment. Product density, flow behavior and temperature must all be considered when the appropriate loading or unloading equipment is being selected.

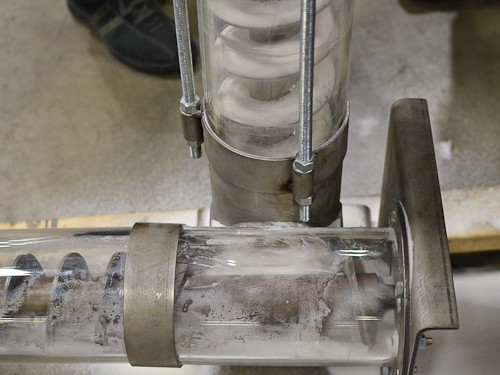

Bag and container dischargers are important pieces of equipment for unloading bulk materials. These tall units have a receptacle area that holds a full bag or container in place while allowing it to be opened from beneath and emptied into a bin using gravity. From here, the material can travel along a conveyor to other stages of the handling process.

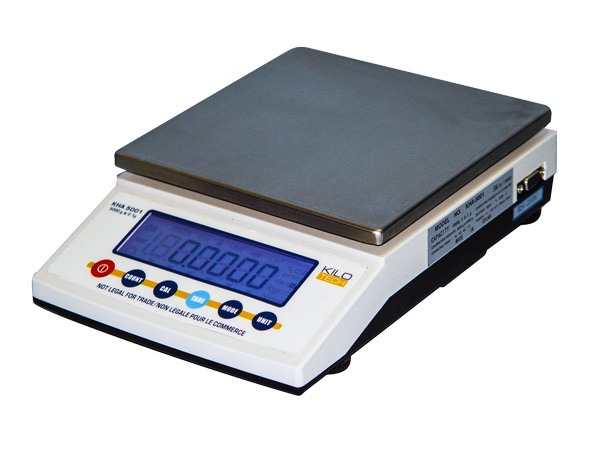

Loading equipment for bulk equipment includes material recovery machines and bulk bag loaders. Material recovery equipment is important in facilities where there is the potential for a high level of wasted material during production. Material can fall out of bags or off of conveyors, but this can be collected and reused as long as it is not for food purposes. After being gathered up, the material can be loaded onto a conveyor that transports it to a hopper feeder and into a bulk bag. Some facilities do this periodically to reduce wasted material. Wet or dry products can even be recovered after they have been packaged if the packaging is damaged or flawed in any way. A recovery machine presses the packaging, forcing the contents out and guiding them into a bin or bulk bag. A bulk bag loader holds an empty bulk bag in position on a pallet beneath a hopper or feed bin as material is dumped into it. The material is added by weight until the bag reaches a preset level. The flow is then cut off until a new bag is placed under the system.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services